3/4", Ganesh SL-20Y2, 2018, Mits 830, Dbl Y-axis, Sub-Spindle, Only 430 HRS

Our stock number:

403800

Click on picture below for larger version

To the best of our knowledge all details listed below are deemed correct.

It is the buyers responsibility to confirm ALL details prior to purchase.

==========================================================

KE-NEW CONDITON.

8 FOR $189,500.00

AND ONLY RAN ONLY PLASTIC

================================================================

Equipped With:

FMB MicroMag 20 Magazine Bar Loader, 12ft bar cap, s/n 28-0531R1617500

Walking beam bar separation system - drops out of the way when running

larger diameter bars

Complete with 2-Guide Channels (10mm & 20mm)

Axial Shift option

MP Systems High Pressure Coolant System, s/n NC08-30-1P-0T-150-CVPV

Harbor HJ-750PSA2 Coolant Chiller s/n LC321457

TriMist Mist Collector

Parts Conveyor

Chip Conveyor

Air Blast

Synchronous Rotary Guide-Bushing Holder

Non-Guide Bushing Holder (Chucker Kit)

Parts catcher

Parts conveyor w/ output ramp & collection bin Cutoff confirmation sweep-

arm switch

Sub-spindle programmable air blast and finished parts ejector

High-Performance "C"-Axis on both the main and sub spindle

Rigid Synchronous Tapping

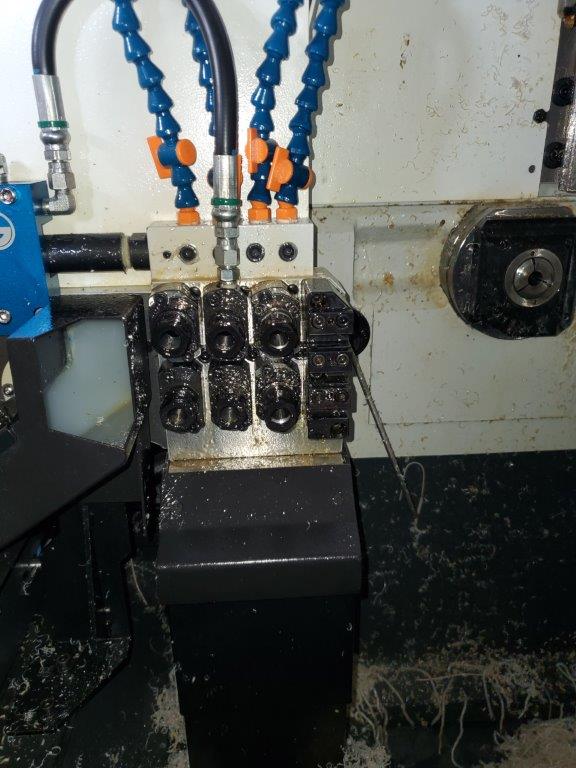

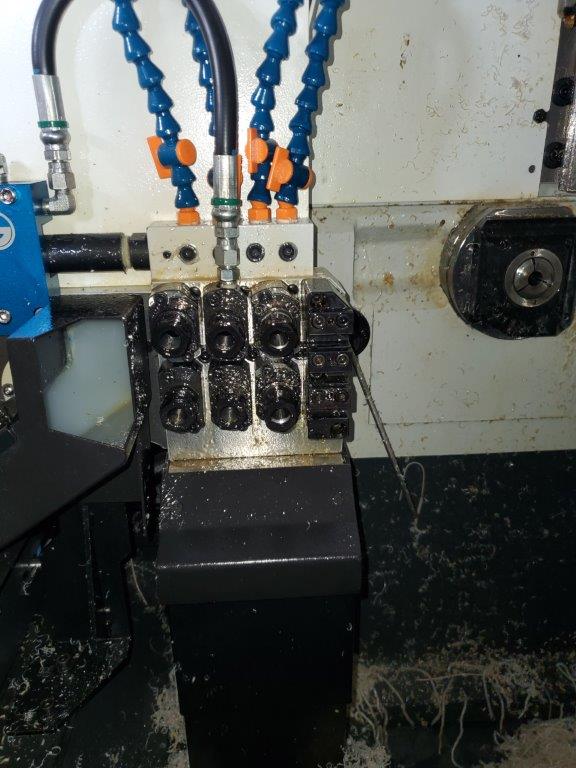

Manifold for 4-High Pressure Oil Ports

Cutting oil chiller system - 18K BTU's (For Machine Thermal Stabalization)

Coolant flow confirmation monitoring switch w/ fault interrupt interface

8-live-tool ER-16 collet spindles (3-not mounted)

3-Postion Z-axis (Live Face) Tool

Collets, TF-25: 3/8", 7/16", 1/2"

Guide Bushings, TD25S: 3/8", 7/16"

(4) Foot pads

Manuals: Ganesh Operations, Parts, Electrical, Mitsubishi M800/M80

Tool Box

** Machine is like New

** Ran only delron

On-time ONLY 430 hours

=======================================

GENERAL SPECIFICATIONS:

Main Spindle:

Spindle Speed/Bearing: 10,000 RPM/5-Bearing Spindle

Spindle Motor: 5 HP

Collet Style for Main/Sub Spindle: Hardinge TF-25S/ S&M TS-25

Synchronous Rotary Guide Bushing: TD25S

Barstock Diameter: 23mm (3/4")

Distance Between Spindles: 23.6" (600mm)

Spindle Centerline Height: 42" (1060mm)

Main Spindle Tooling:

OD Turning Tool Holders: 6 - 12mm

ID Internal Tool Holders: 4 - 22mm

ID Deep Hole Drill Positions: 2 - 22mm

Cross Slide Live Tools: 5 - ER16 (8,000 RPM)

Drilling/Tapping Capacity: 10mm Drilling / M8 Tap

Cross Drilling/Tapping Capacity: 8mm Drilling / M6 Tap

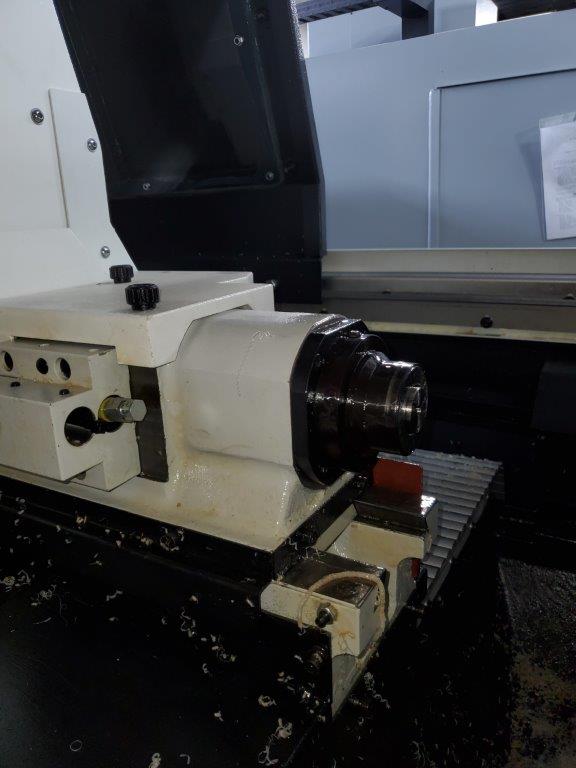

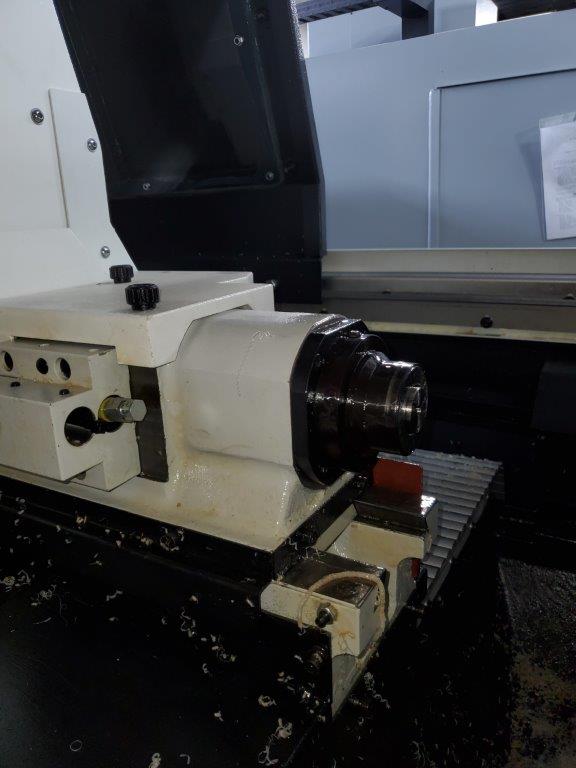

Sub-Spindle:

Spindle Speed/Bearings: 8,000 RPM / 4-Bearing Spindle

Sub-Spindle Motor: 5 HP

Collet Style for Main/Sub Spindle: =Hardinge TF-25S/ S&M TS-25

Barstock Diameter: 23mm (3/4")

Workpiece Length for Front Ejection: 110mm

Sub-Spindle Tooling:

OD Turning Tool Holders: 3 - 10mm

ID Internal Tool Holders: 4 - 22mm

ID Internal Tool Holders: 3 - ER-16 Fixed Tools (3/8")

Sub Spindle Axiel Live Tools: 3 - RE-16 Live Tools (4,000 RPM)

Backworking Machining Length: 6.1" Turning Length / 3.14" Boring

Drilling/Tapping Capacity: 10mm Drilling / M8 Tapping

Cross Drilling/Tapping Capacity: 8mm Drilling / M6 Tapping

Axes:

Main Spindle Stroke: 9.840" Single Stroke (250mm)

Turning Length (Rotary Bushing): 7.48 (190mm)

Turning Length (Without Bushing): 2.36" (60mm)

X1, Y1, Z1, X2, Y2, Z2 Rapids: 944 IPM (24m/minute)

X1, Y1, Z1 Axis Motor Power: 1 HP

X2, Y2, Z2 Axis Motor Power: .67 HP

Minimum Input Unit: 0.0001"

Power: 220 Volts/3 Phase/ 60hz/ 60 Amps

Sold As-Is, with a start-up warranty, FCA Colorado

Machine: 120" x 60" x 84" 6,000 lbs

Barfeed: 230" x 32" x 54" 2,500 lbs

Chip Conveyor: 94" x 22" x 38" 1,500 lbs

Chip Pan 1: 55" x 48" x 13" 150 lbs

Chip Pan 2: 49" x 37" x 19" 180 lbs

HPC: 46" x 24" x 46" 500 lbs

Mist Buster: 30" x 28" x 24" 225 lbs

Oil Chiller: 27" x 23" x 59" 300 lbs

Chip Cart: 39" x 22" x 33" 190 lbs

RETURN

to listing display

RETURN

to our home page