|

8" x 5" OKUMA ‘TWIN SPINDLE’ TURNING CENTER QUOTE# 54-336Z

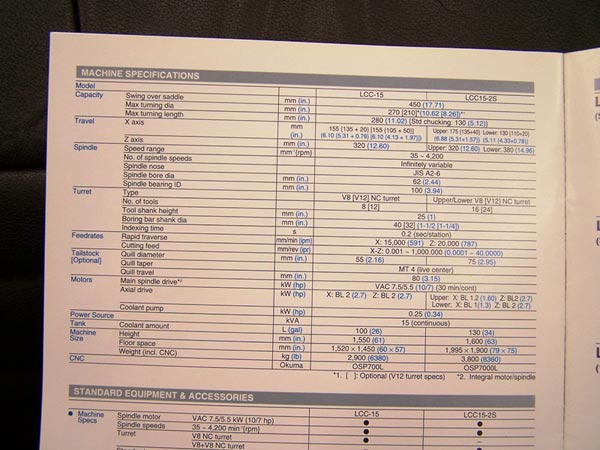

MODEL/TYPE:LCC-15-2S / Twin Saddle/4 Axis AGE: New - 1999

Note: This is a twin spindle twin saddle full 4-Axis turning center with 2 Part Loaders & an Automat

c part turn-over station, Gantry type loaders and a 20 station stackable work table and an Automatic

Gauging system, and a Flex Link conveyor (output) system and chip removal system

SPECIFICATIONS & DESCRIPTION:

Maximum swing over saddle:17.71" Dia

Maximum ' Z' Travel: main spindle: upper: 12.60” / lower: 14.96”

Maximum truning dia:8.260” dia

Maximum turning length:5.12”

Number of controlled axis:(4)

Spindle Bore - hole thru spindle: Main spindle: 2.44" Dia

Spindle speed range35 - 4200 RPM

Dual Turret Design: upper / lower upper: 2-12 stations / 2-8 stations

Turret Tooling capacity: OD & ID Turrets1-1/4” dia shank

Rapid traverse787 (Z-axis)

Cutting feed rates0.0001: - 40.0” per rev

High Pressure Flood Coolant system

Machine Gross Weight - approximately 8400 #

Floor Space Dimensions:80” x 75”

EQUIPMENT & SPECIAL FEATURES:

Full way covers (2) No. A2-6 (8”) Hydraulic Power Chucks

Flood coolant system - coolant thru turret Rear Chip Conveyor system

(2) Model OGL-5 Gantry type Loader units 20 station stackable work table

Flex Link conveyor output unit Chip removal conveyor system

Pulcom-V Auto Gauging system (note – this device is not working properly)

ELECTRONICS:

Equipped with an OSP 7000L series CNC Control System -Full 4-Axis

Linear and circular interpolation - Full CRT w/multi axis display - MDI system, Absolute, Cutte

Comp.

Conversational Type CNC - IGF on-line programming, Auto load monitoring - Color Graphics

ELECTRICS: 10/7 HP VAC Main Spindle drives - Axial drive: Upper: 1.6 HP (X) / 2.7 HP (Z) /

Lower: 1.3 HP (X) / 2.7 HP (Z) - Coolant (1/3 HP) - 230/460

VAC 3 PH 60 Hz

Quote# 54-336Z continued – page 2

CONDITION: Machine is in very good condition, currently set up and operating in plant

where it may be inspected under power.

LOCATION: Missouir Plant, near Springfield

RETURN

to our home page