|

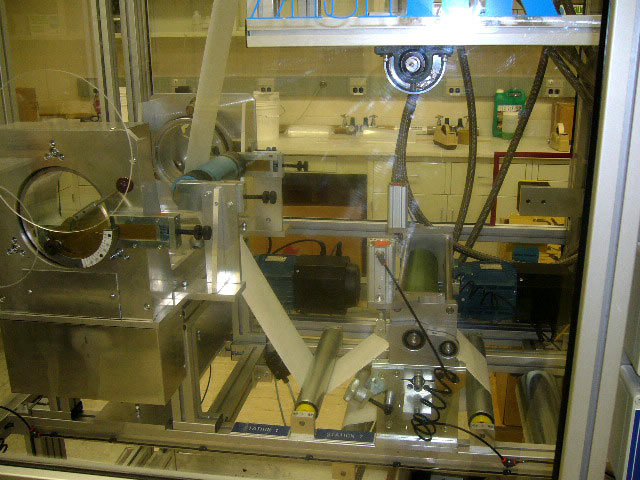

MODEL/TYPE: Flexographic Print & Coater for Paper/Plastic/Foil

Age: New - 2003

SPECIFICATIONS & DESCRIPTION:

This is a custom print & coating line designed to treat various types

of paper, plastic and foil products utilizing a Flexo-graphic, rotary

Screen / Slot die technique and for laminating two (2) plies - This is

a flexible web laminating process - It is presently set-up to use

rotary screens. The OEM is: RK Print-Coat Instruments Company

General Line specifications:

Product capacity: 12" W - 3" Dia core web materials

Product materials: Paper - Plastic - Foil

Line footprint 25’L x 5’W x 6’H

Description of the Line:

Equipped with three stations - in line, continuous operation

-Station #1: Printing & Coating application - includes printing &

coating heads

'S' wrap material flow - this station provides speed control and

Delaminates the liner main unwind

Also equipped with a secondary rewind after the delaminating

Main rewind unit - used to rewind the finished substrate after cooling

Equipped with web-guides

-Station #2: Laminating application - includes an unwind device for

laminating 2-plies

This station is equipped with hot-water heated rollers

Equipped with web-guides

-Station #3: Print application - This is an alternate print heat

station

Includes an unwind device for laminating 2-plies

(2) water-heated rollers to preheat the web prior to the lamination

process, and

(2) cooling rollers to condition the web before re-winding

Other equipment in the line:

Conair water heater unit - Diaphragm & mono-pumps

Dryer system - 6 dryer module unit - Web Guides & Wind ups

Screen washers 1 & 2 - Operator Controls & Electronics

ELECTRICS: 220/440VAC - 3-Ph - 60Hz

CONDITION: Line is in very good condition - currently set up and in

place, no longer in operation

LOCATION: Delaware Plant - near Wilmington

RETURN

to complete inventory display

RETURN

to our home page