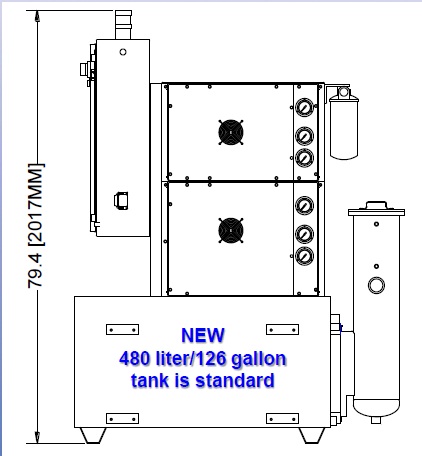

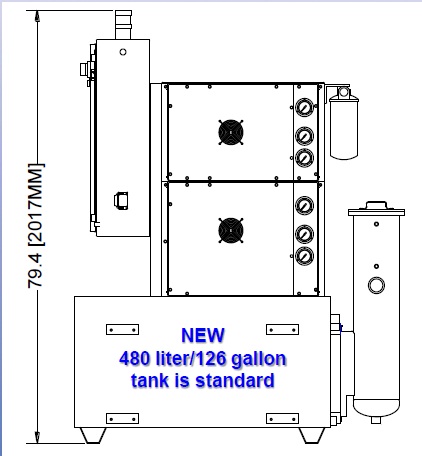

ChipBLASTER WV2-120, 6-32 GPM, 1500 PSI, 126 Gal., 2 independent modules

Our stock number:

316275

Click on picture below for larger version

General Specifications As Per Brochure

Max. Pressure: 100 Bar

1500 PSI

Coolant Volume: Automatically Variable Volume

24 - 120 Liters / Minute

6 - 32 GPM

Tank: 480 Liter / 126 Gallon

Filtration: Dual Parallel Bags

Outlets: 2

The WV2-120 can operate as two completely independent 60 liter (16 gpm)

modules or combine to give you high pressure AND very high volume

(120 liters) to one outlet at any time during the same program!

Standard Configuration:

The ChipBLASTER WV2-120 is fed by a transfer pump that draws from the machine

tool sump, through the filter vessel to the integral 480 liter (126 gal) tank.

When the machine tool calls for coolant, the filter pump(s) draws the coolant

from the ChipBLASTER tank and pumps through the post (safety) filter to the

inlet of the positive displacement pump. The coolant then flows at high

pressure through a series of distribution and safety valves and on to the

machine tool.

M Code Requirement:

1 "M" Code Controlled Signal is Required to Operate as One High Volume Outlet.

2 "M" Code Controlled Signals Are Required to Operate as Two Independent

Modules.

3 "M" Code Controlled Signals Are Required to Operate as Two Independent

Modules AND One High Volume Outlet

24 VDC,110 VAC or 240 VAC signal is acceptable needed.

Required Electrical Power:

82 amps, 230 VAC, 3 Phase, 60 Hz

41 amps, 460 VAC, 3 Phase, 60 Hz

49 amps, 400 VAC, 3 Phase, 50 Hz

Ideal for Machine Tools Up to 60 Kw (80 HP), Dual Turret Lathes & 50 Taper

Mills.

See brochure for more details and options.

RETURN

to listing display

RETURN

to our home page