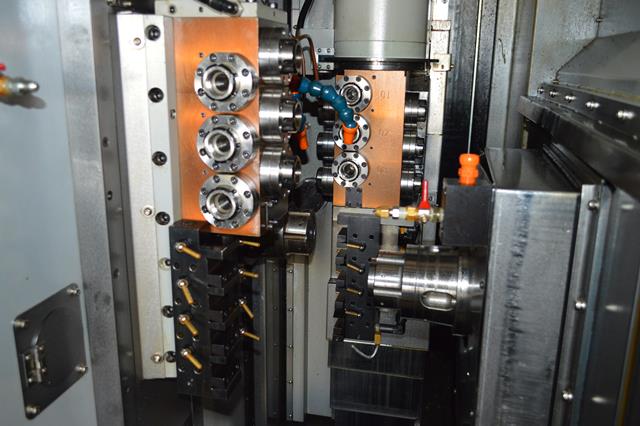

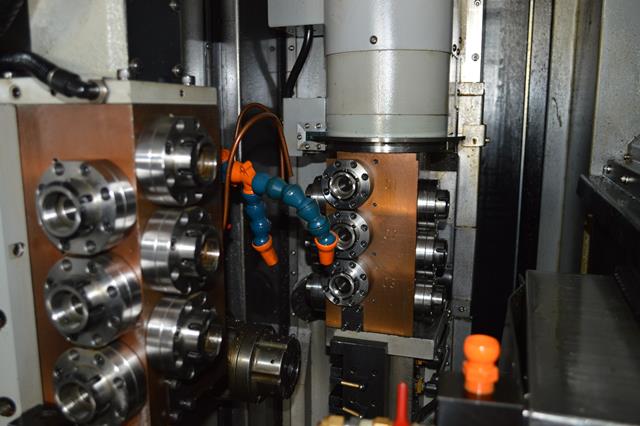

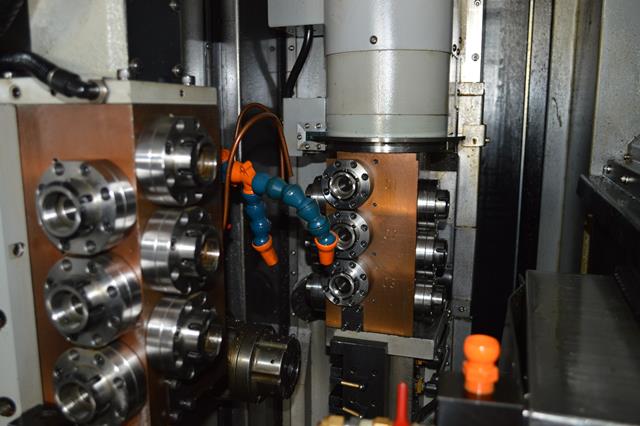

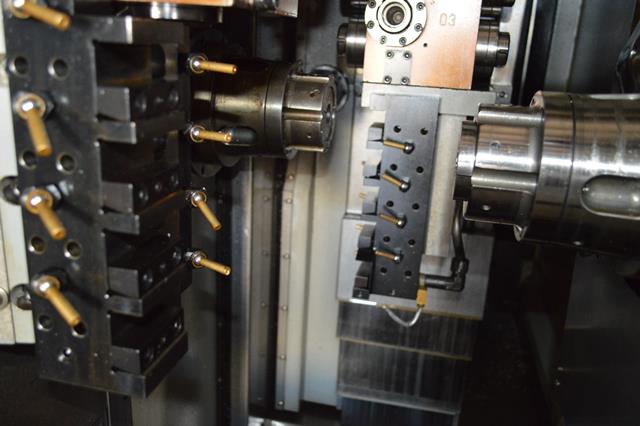

Ganesh, GenTurn 52BY2, MITS M720, 2", MillTurn, 9-Axis, B-Axis, Double Y-Axis

Our stock number:

402251

Click on picture below for larger version

General Specifications As Per Brochure. To the best of our knowledge details

below are deemed correct. It is the buyers responsibility to confirm prior to

purchase.

Equipped With:

2" Bar Capacity

15 HP Dual Opposing Spindles

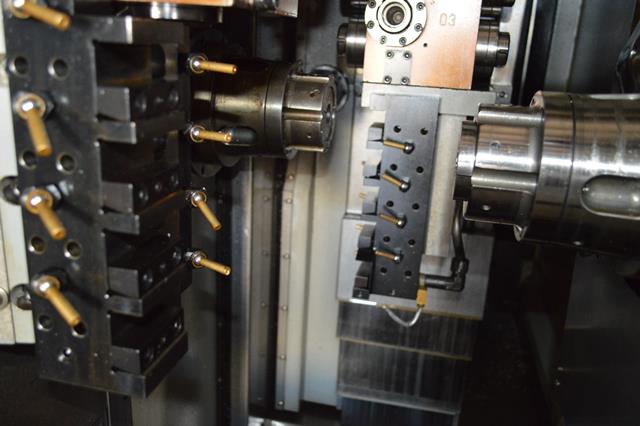

B-Axis & Dual Y-Axis for both Front and Backworking

36 Tool Positions w/ 18 Driven tools, 12 for B-Axis

80 gallon coolant tank

Mistbuster 850 Mist Collector

High Pressure Collant

Edge Rebel V-65 Servo Bar Feeder

Specifications:

MAIN SPINDLE Integral Built-in Motor Spindle

Maximum bar diameter: 2.008"

Spindle Nose: A2-5

Collet size: Traub TRB-52

Maximum spindle speed: 6,000 RPM

Servo Spindle motor horsepower: 15-HP peak, 10-HP 30-min. rated

X1, Y1, Z1 AXIS

X1, Y1, Z1 axis servo motor: X1-1.3 hp Y1/Z1-2.0 hp

X1 axis travel: 10.63"

Y1 axis travel: 18.11"

Z1 axis travel: 9.84"

Minimum programmable input: 0.00004" resolution

X1, Y1, Z1 rapid travel rate: 1181 IPM (30m/min)

MAIN SPINDLE TOOLING

Number of driven tools: 6 axial and 6 radial driven

Driven tool motor power: 5-HP

Driven tool spindle speed: 6,000 RPM

Driven tool collet size ER-20 (up to 1/2" tool shank)

O.D. turning tools 5-20mm O.D. holders available

I.D. boring tools 5-25mm I.D. bores available

SUB SPINDLE

Type: INTEGRAL BUILT-IN MOTOR SPINDLE

Maximum bar diameter: 2.008"

Collet size: Traub TRB-52

Maximum spindle speed: 6,000 RPM

Servo Spindle motor horsepower 15-HP peak, 10-HP 30-min. rated

X2, Y2, Z2 AXIS

X2, Y2, Z2 axis servo motor: X2/Z2-1.3 hp/Y2-2.0 hp

X2 axis travel: 18.89"

Y2 axis travel: 18.11"

Z2 axis travel: 10.63"

X2, Y2, Z2 rapid travel rate: 1181 IPM (30m/min)

Minimum programmable input: 0.0001"

SUB SPINDLE TOOLING

Number of axial driven tools: 3 axial, uses ER-20 collets

Number of radial driven tools: 3 radial, uses ER-20 collets

Driven tool motor power: 2.7-HP (2.0kw)

Driven tool spindle speed: 6,000 RPM

Driven tool collet size: ER-20 (up to 1/2" tool shank)

O.D. turning tools: 4-20mm O.D. holders available

I.D. boring tools: #4 - 25mm I.D. bores available

COOLANT SYSTEM - 300 PSI

Size: 80 Gallon tank,

Pumps: 3 pumps with flow control

ELECTRICAL REQUIREMENT 110-Amps,42kva,220 vac, 3 Phase

AIR REQUIREMENTS: 85 psi, 20-cfm

MACHINE WEIGHT: 12,345 LBS

MACHINE DIMENSIONS: 142" x 85" x 82" w/ chip conveyor

GenTurn 52-BY2 9-Axis Mill/Turn Center - Production Package

9-Axis Turning Center with B-Axis, and both Dual "Y" Axis & "C" Axis,

including:

2-Traub-52 "Dead-Length" collet chucks. Automatic power shut-down.

36-Tool positions including 18-Driven Tools with ER-20 collet spindles

included,

Parts catcher with parts conveyor, chip conveyor, fluorescent worklight

Barloader interface, headwall air blast and coolant outlets for main and sub

spindle,

Sub-Spindle programmable air blast, oil flush, and finished parts ejector

215 PSI High-Pressure coolant pump for cutting tools with coolant flow sensor

monitor.

Dual 1-HP coolant pumps for headwall & chip flush with coolant flow sensor

monitoring.

RETURN

to listing display

RETURN

to our home page