|

To the best of our knowledge all details below are deemed correct. It is the

buyers responsibility to confirm prior to purchase.

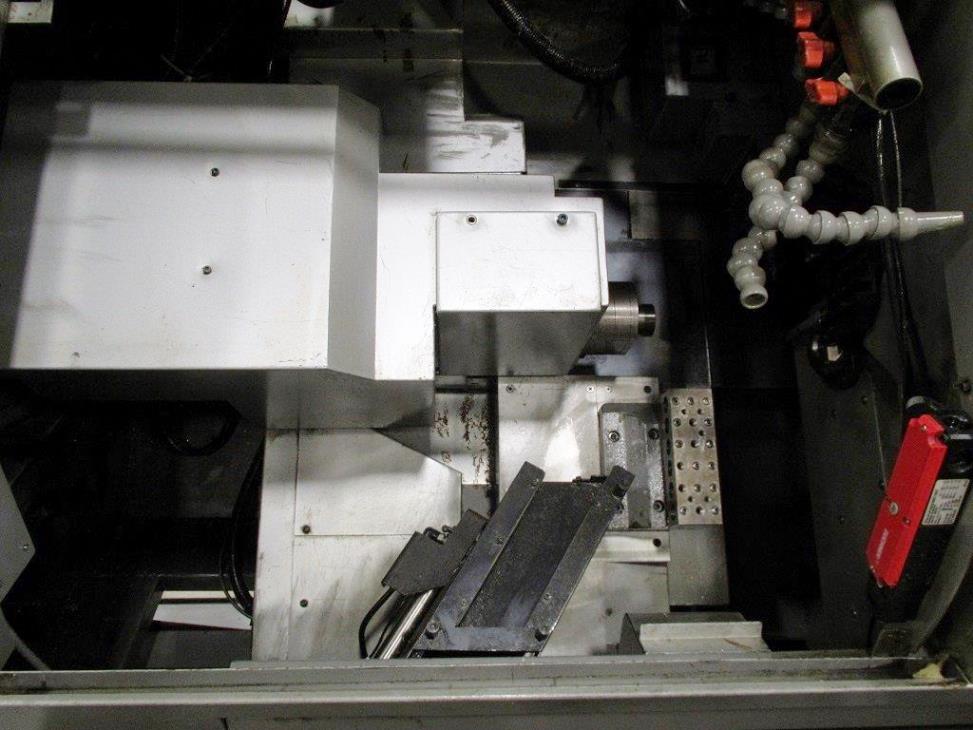

Equipped with:

Cincom (mitsubishi meldas-600) control

Long parts conveyor

(2) live tools

Shot separator unit

Program work area size 20m (memory 40m)

Custom macro

Sub micron/sub inch command function

Inch specification

Main spindle 1-degree indexing function

Main spindle c-axis function

Back spindle 1-degree function

Back spindle c-axis function

b/sp constant surface speed control

Back spindle chasing function

General specifications for a C16 IX as per brochure

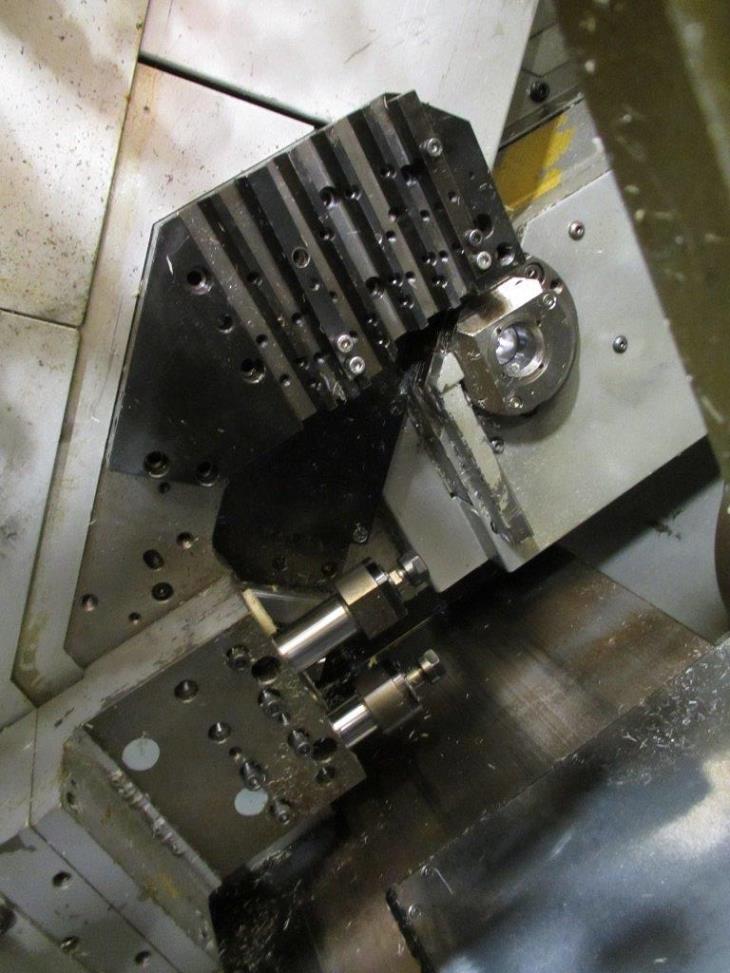

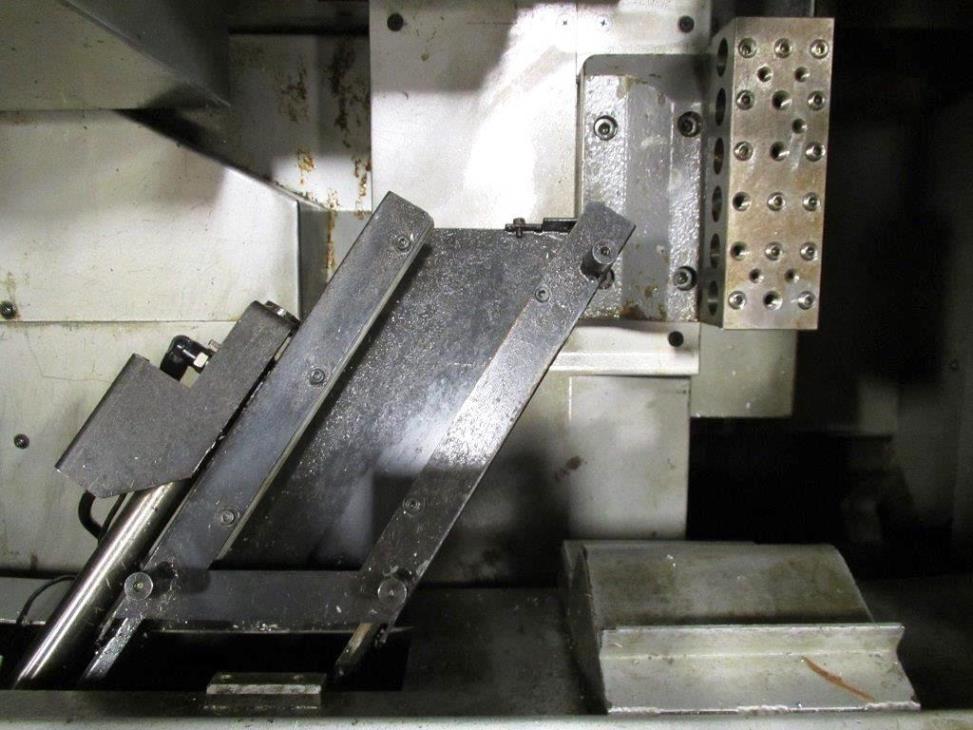

The "x + z axis control modules" have been added to the opposite tool post and

sub spindle respectively in the C16 type IX. Combination of the radial tool

post, which is common to the c-series models, and the opposite tool post's of

2-axes control improves simultaneous machining performance. The combination

enables simultaneous machining (3-axes superimpose) of "front drilling - outer

diameter machining - back drilling

Control: Cincom System M6

Axes: 7

X1,Y1,Z1,X2,Z3

Max. machining diameter: 5/8"

Max. machining length: 7.87" per chucking

Max. chuck diameter of the back spindle: 5/8"

Max. workpiece length for the front side

collection from the back spindle: 3.5"

Main Spindle Index: 1 degree Std (full C opt)

Sub Spindle Index: 1 degree Std (full C opt)

Tooling size:

tool (gang tool post): 3/8" x 3/8"

sleeve: 3/4"

# of tools: 6 turning

4 rotary

6 front drilling

6 back drilling

Main spindle speed: 200 - 10,000 rpm

Rotary tool spindle speed: 200 - 8,000 rpm

Back spindle speed: 200 - 10,000 rpm

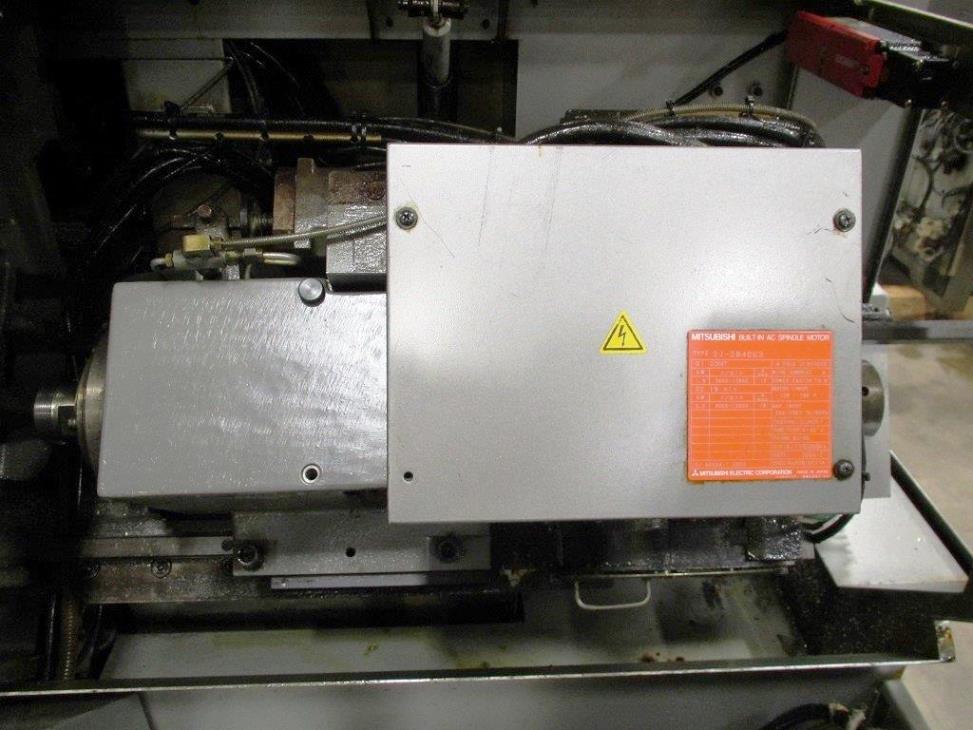

Main motor: 2hp/3hp

Tool spindle motor: 1hp

Back spindle motor: .5hp/1hp

Coolant motor: .3hp

Machine: 89" x 41" x 68" 4,000 lbs

Chip/Coolant Tank: 48" x 33" x 224" 150 lbs

Pallet w/misc tooling: 40" x 48" x 38" 500 lbs

RETURN

to our home page