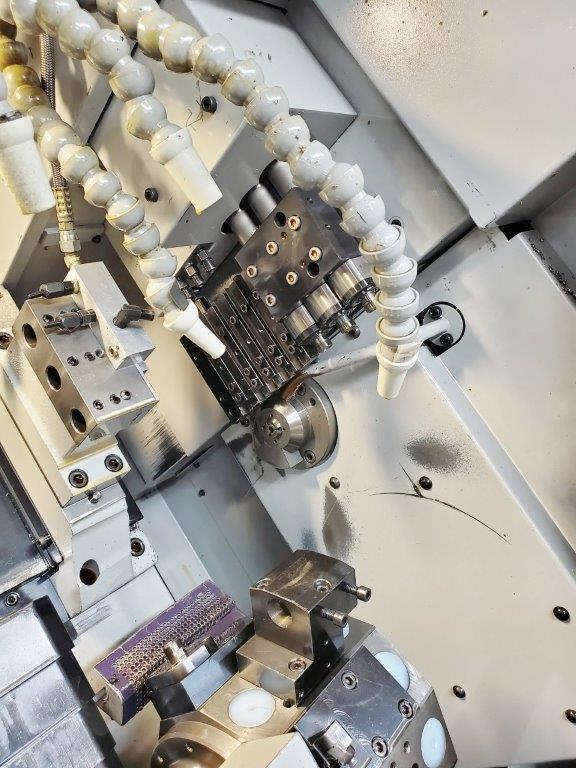

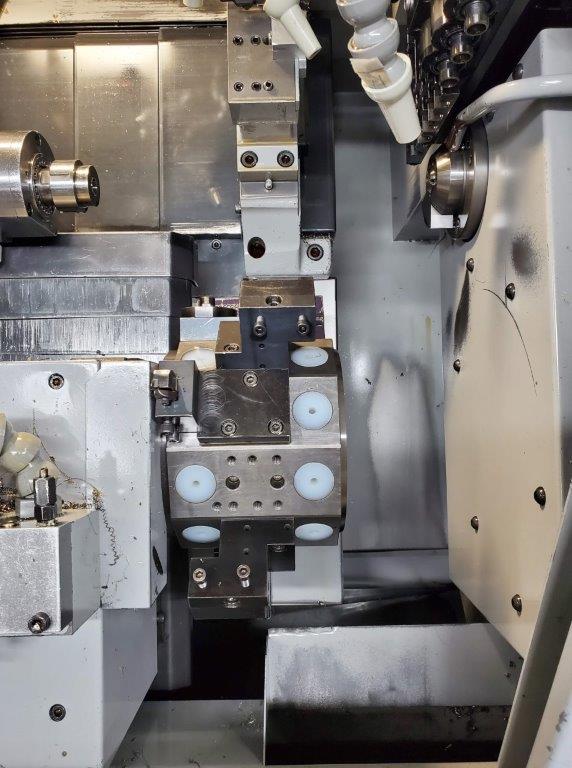

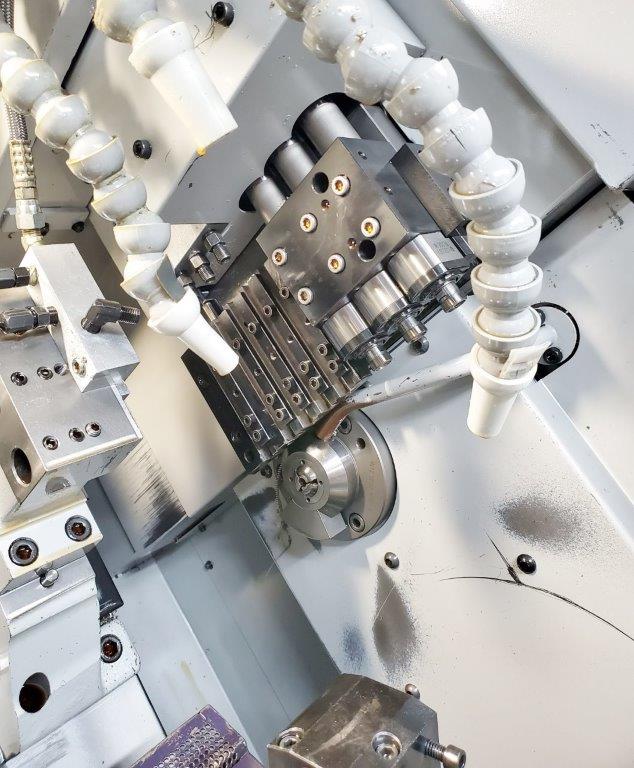

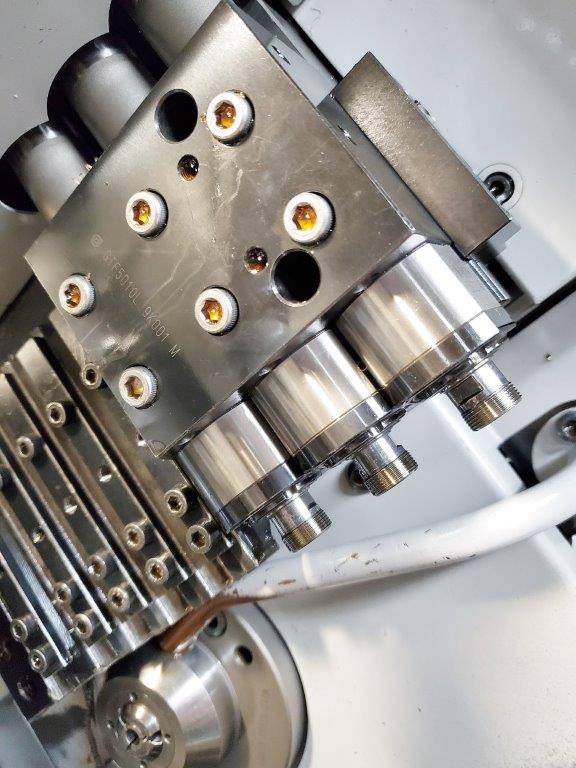

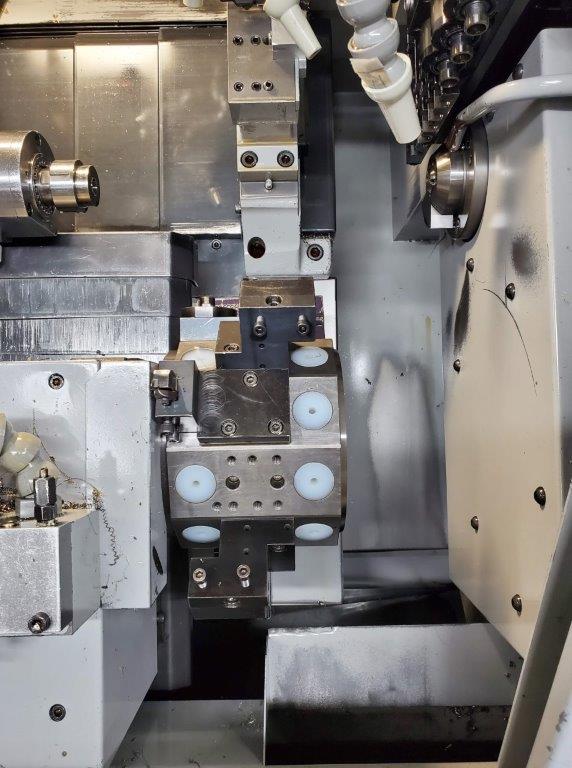

1/2", Citizen M12, Cincom, 2000, LNS Hydrobar, HPC, Live Tool, Rotary GB

Our stock number:

404468

Click on picture below for larger version

To the best of our knowledge all details listed below are deemed correct. It

is the buyer's responsibility to confirm all details and we encourage an

inspection of the machine(s) and accessories prior to purchase.

Equipped With:

Windows Based Cincom CNC Control

LNS Super Hydrobar 3.12 HS-4.8 Barfeed

Cool Blaster B-CBDHD-4L High Pressure Coolant System

Coolant Filtration System

Parts Catcher

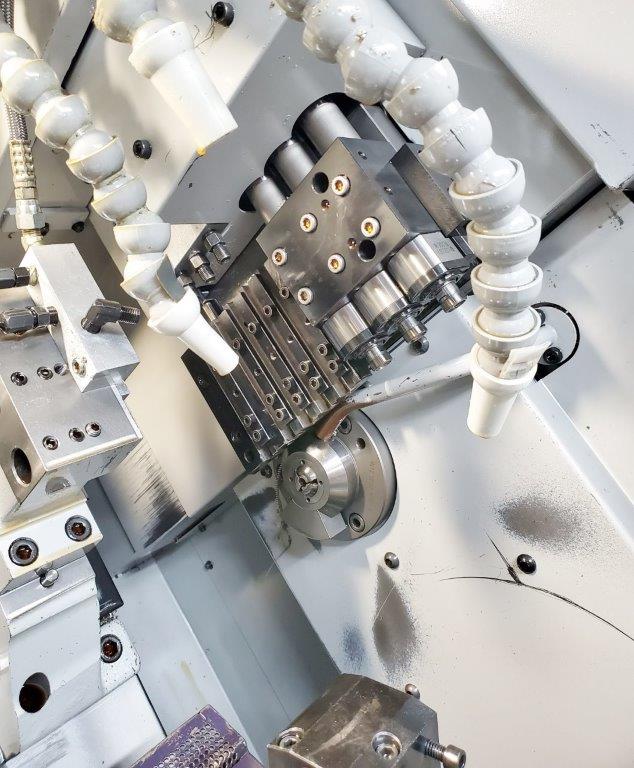

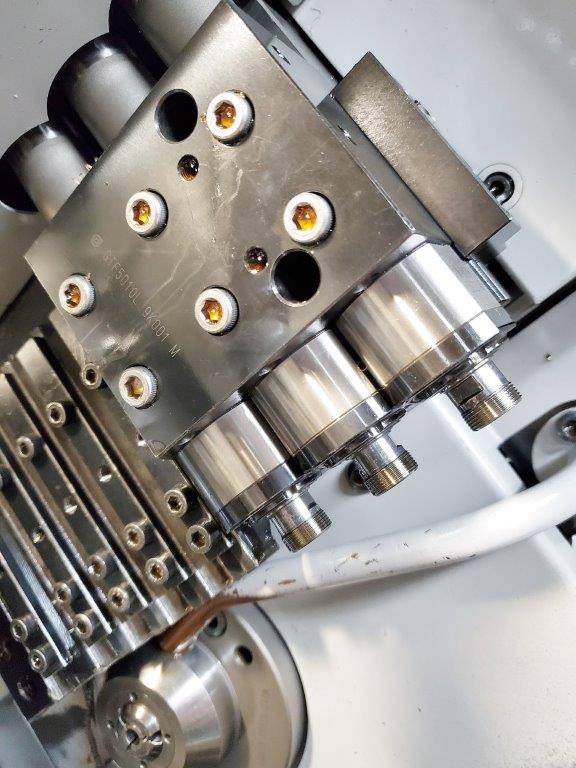

Synchronized Rotary Guide Bushing

Programmable Work Area of 20M (Memory 40M)

Custom Macro, Inch Spec, Back Spindle

Surface Speed, Milling Interp

Main/PO Spindle Synch, Synch Tapping (Back Spindle)

Chasing Function

Canned Cycle for Drilling, Constant

Synch Tapping (Main Spindle, Live Tool)

Cutoff Detector

Tool Life Management 1

Tooling Included:

(7) Assorted Live Turret Tools

(10+) Assorted Stick Tools

(35) Assorted New and used Guide Bushings

Very Large Assortment of New and Used Main/Sub Spindle Collets

Assorted ID and OD Turret Tool Holders

General Specifications:

Machining Diameter: .472" (12mm)

Machining Length: 7.87" (200mm)

Spindle Speed: 12,000 RPM

Main Spindle Indexing: Full C-Axis

Sub Spindle Speed: 10,000 RPM

Sub Spindle Indexing: 1 Degree

Rapid Traverse: 787.4 IPM (20M.Min)

Gang Tool Post

Turning Tools: 5

Rotary Tools: 3

Rotary Tool Speed: 8,000 RPM

Turret Tool Post

Tool Positions: 10

Rotary Tool Speed: 6,500 RPM

Backworking Tool Post

Tool Positions: 3

*Only Cutting Oil Used*

By Using the Intermediate Indexing Function, 20 or More Tools can be Attached.

The Full Servo System has 13 Axes in all Including the Turret Operation in

which Hydraulic Pressure is Used for Positioning.

RETURN

to listing display

RETURN

to our home page