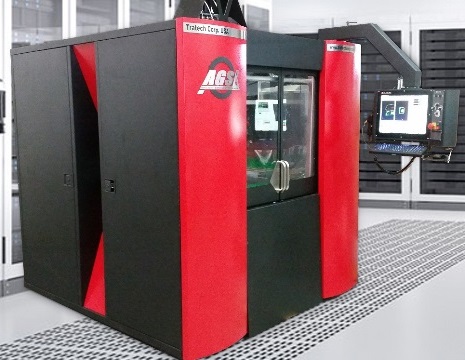

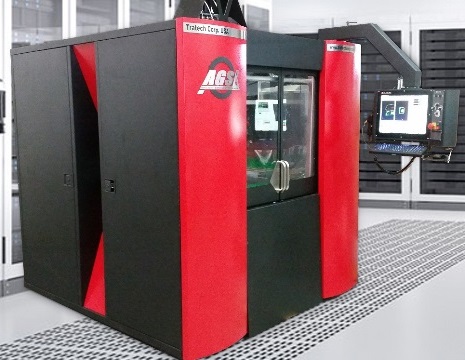

20"X, 20"Y, 19"Z, Advanced Grinding Sys (AGS) 42-3A, Sintered Ceramic Grind/Mill

Our stock number:

401818

Click on picture below for larger version

To the best of our knowledge all details listed below are deemed correct.

It is the buyers responsibility to confirm ALL details prior to purchase.

Special Notes from the OEM......

The Tratech Advanced Grinding System(AGS) 42-3A is a breakthrough in the

advancing ceramics industry, with productivity improvements up to 10x times

faster than anything else today. The AGS is a specially built high speed

grind/mill machine designed specifically for the demanding needs of machining

fully sintered ceramics at a competitive price point. Designed to grind and

machine materials such as quartz glass, sapphire, boron carbide, alumina oxide

and zirconia nitride, providing unmatched machining capability, improved

quality and lower overall production costs.

General Specifications:

Table Size: 21" x 26" (533mm x 660mm)

Travels: X = 20"

Y = 20"

Z = 19"

T-Slot Spacing: 4" (101.6mm)

Load on Table: 350 lbs (158kgs)

Spindle Speed: 42,000 RPM

Tool Interface: HSK-E40

Torque: 4.77 lbs @ 14700 RPM (6.5Nm)

Voltage: 240/480 Volts

Hydbrid Ceramic Bearing, Vibration Measuring System on 3-Axis ("G" Meter)

Feed Rate: 500in/min (12m/minutes)

Tool Changer: 255 Tools Max

Interchangable 16 Tools

* Tratech Corp. Proprietary tool change technology allows 16 active tools to

be loaded in seconds, with an additional 255 in tray storage. The trays are

hot swap enabled without interrupting active machining cycles. *OTF (On The

Fly) System Allows for 16 Loaded Tools in Less Than 30 Seconds*

Air Requirements: 100 PSI/ 6.5 CFM (6.8 Bar/183L/Min)

Coolant: 57 Gal (215 Liters)

Chiller: Heat Exchanger, Digital Control

Mist Control: Turbine Unit w/ Hepa Filter

Machine Dimensions: 79" x 79" x 100" (2M x 2M x 2,57M)

Machine Weight: 9,800 lbs (4,222kgs)

CALL TODAY:

SET UP A CONFERENCE CALL, DISCUSS YOUR NEEDS / REQUIREMENTS WITH AN EXPERT

RETURN

to listing display

RETURN

to our home page