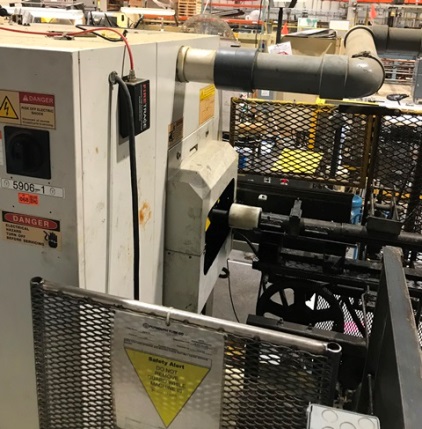

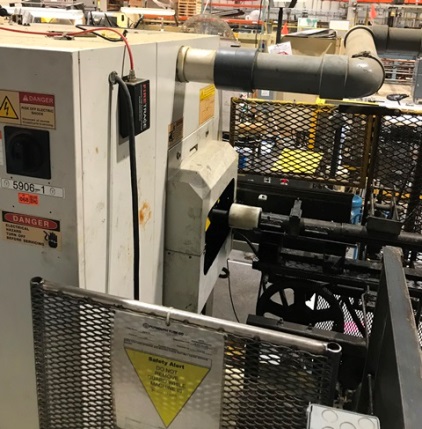

GANESH CYCLONE 32GTS, SUPER 900, 1-7/16", 2008, DBL Gang-tool, Dual Spindle

Our stock number:

399106

Click on picture below for larger version

All specification from OEM brochure, buyer should confirm all details

INCLUDES

Bar feed, Hydraulic, single tube

Long Parts Attachment

Misc ID & OD tooling

Chip Conveyor, Mist Collector, Fire Trace, Coolant Chiller

Control: Ganesh Super 900T Advanced Multi-Tasking

MAIN & SUBSPINDLE

Spindle Motor 10HP (7.5 kW)

Maximum Speed 6,000 rpm

Collet Nose Brown & Sharpe #22 or Traub A-32

Drawtube ID 1.456" (37mm)

Traub TRB-A32 Collet Capacity 1.25" (32mm)

Spindle Center Height to Table 3.464" (88mm)

Spindle Center Height to Floor 42.2" (1070mm)

MACHINE AXIS

X-Axis Travel: Twin cross-slides 13" (330mm)

Z-Axis Travel: Twin opposed spindles 10.63" (270mm)

Main Features:

Simultaneously Machine on the Main and Sub Spindle

"C"-Axis on both spindles for Live Tool Applications

Dual Parallel Gang-Tooled Slides for Fast Production

Rigid Tapping on both spindles

Integral Lathe Motor Spindles

Parts Catcher with Parts Conveyor

Chip Conveyor

High Pressure Coolant Option Included

Mist Buster / Collector Option Included

** Ganesh (OEM) machine Description:

The GANESH CYCLONE-32 GTS is a 6-axis 1.25" (32mm) bar diameter twin spindle

CNC production turning center with a fully synchronized C-axis on both the

main and subspindle. The configuration produces shorter cycle-times because

the Counter Spindle works simultaneously with the Main Spindle. This lathe

features dual parallel gang tooled slides sitting side-by-side that allow

flexibility in tool placement, including the use of driven tools. Both the

main gang slide and the subspindle gang slide work completely independently,

allowing for shorter cycle times because the front and the back of a workpiece

can be machined at the same time.

* Ganesh Super 900T Advanced Multi-Tasking

PC-based control with 256 MB memory, 96-tool offset pairs, and a 15" LCD

color monitor

Program check-out feature using MPG handwheel to advance and retract axis

moves at the speed that the handwheel is turned to maintain a high level

of process control

Toolpath shown in a multiple color overlay displaying each tool

Tool-Life Management

Over 20-standard canned cycles for efficient program development

Advanced drilling and tapping servo synchronization for shorter cycle times

Cylindrical Interpolation transforms the cutting path from a plane to a

cylinder for engraving etc.

Polar coordinate interpolation to synchronize linear axis motion to rotary

workpiece motion

Ladder diagram for extensive machine condition evaluation and diagnosis

Parameter setting pages by group layout with complete description in clear

text

NC file name storage with complete record of start time, total time and

output quantity.

RETURN

to listing display

RETURN

to our home page