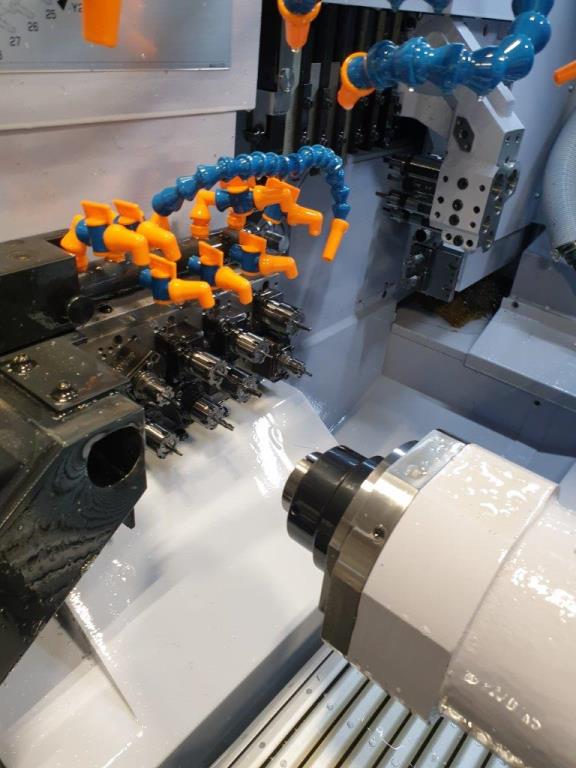

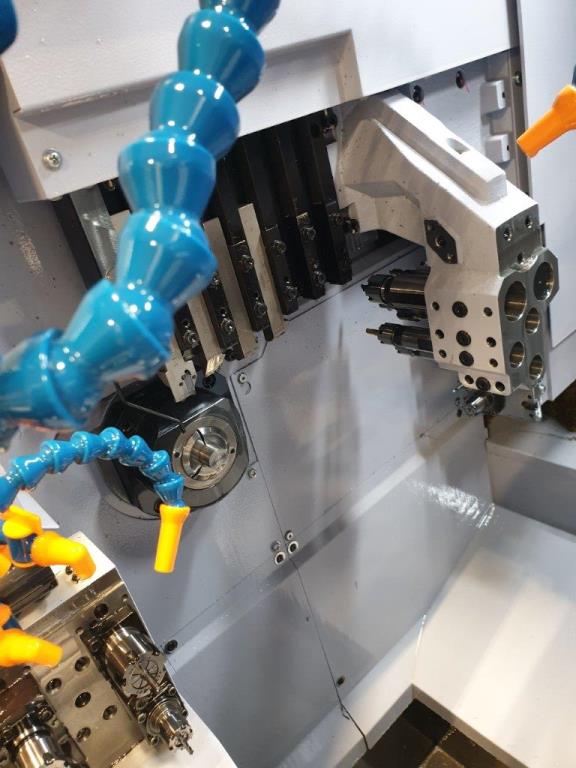

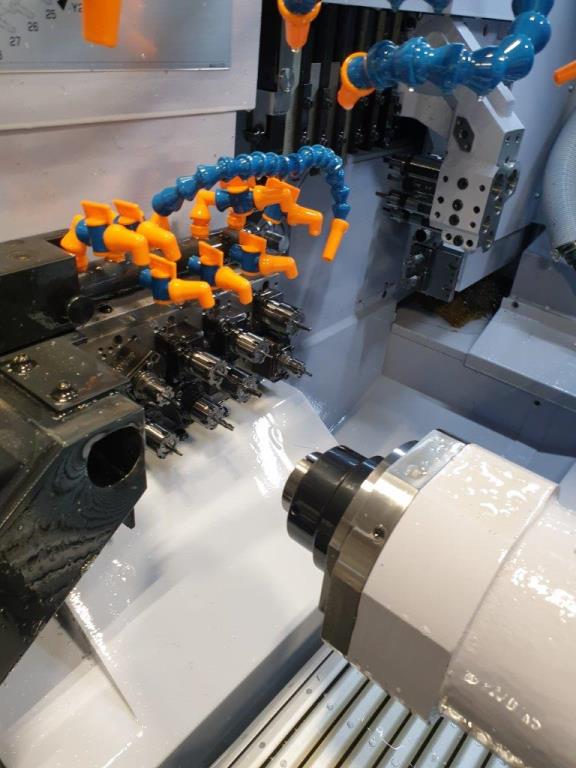

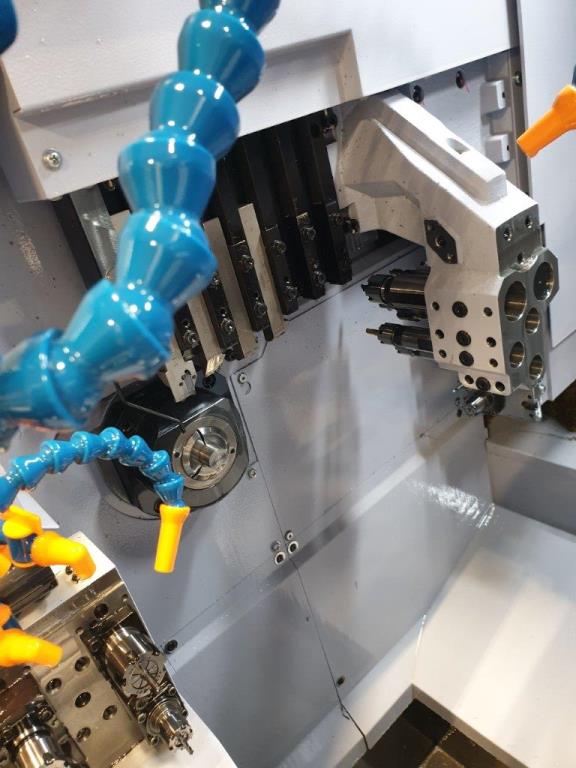

1 1/4", STAR SR32JIIB, FANUC 32I-B, 2018, Convertible, HFT, Iemca Boss 338

Our stock number:

403439

Click on picture below for larger version

To the best of our knowledge all details listed below are deemed correct.

It is the buyer's responsibility to confirmed prior to purchase.

Equipped With:

Iemca Boss 338HD Magazine Bar Feed Installed 2019

Filtermist

HFT - High Frequency Turning Software ($14K value)

Approx 800 hours

Standard Machine Specifications

Machining Diameter 32mm(1-1/4in)

Max Headstock Stroke

Standard 320mm(12-19/32in)

R.M.G.B. type 286.5mm(11-9/32in)

N.G.B. type Bar diameterx2.5(Max.80mm)(Max.3-

5/32in)

Number of tools 6 tools

Tool shank 16mm

5 Spindle Sleeve

Number of tools Front 5 tools

Rear 5 tools

Max. drilling capability 13mm(33/64in)

Max. tapping capability M12xP1.75

Power Driven Attachment

Number of Tools Cross milling 3 tools(ER20)+

Cartridge type 2 Pos

Cross milling 6 tools(ER16)

Max Drilling capability 10mm(25/64in)

Max. Tapping capability M8xP1.25

Spindle Speed Cross milling:Max.6,000min-1

Cartridge-type tool:Max.8,000min-1

Drive motor 2.2kw(continuous)/4.0kw(5min./30%ED)

Rapid feed rate 35m/min ( X1, X2,Y1, Z1, Z2 ),

24m/min ( Y2 ) : type B only

Main spindle indexing C-axis control

Main spindle speed Max.8,000min-1

Main spindle motor 7.5kw(continuous)/11.0kw(10min./25%ED)

Coolant tank capacity 255 liter

Dimensions (WxDxH) 2,690 x 1,345 x 1,780mm

Weight 4,100 kg

Power Consumption 8.8 KVA

A-weighted sound pressure Max.77dB

Max. chucking diameter 32mm(1-1/4in)

Max. length for front ejection 125mm(4-59/64in)

Max. parts projection length 45mm(1-49/64in)

Unit especially for backworking

Number of tools 6 tools(type A)

8 tools(type B)

Max. drilling capability 13mm(33/64in) stationary tool

8mm(5/16in) power driven tool

Max. tapping capability M10xP1.5 stationary tool

M 6xP1.0 power driven tool

Power-driven att. spindle speed Max.6,000min-1

Power-driven att. drive motor 1.0kw(continuous)/1.2kw(5min./30%ED)

Sub spindle indexing angle C-axis control

Sub spindle speed Max.8,000min-1

Sub spindle motor 3.7kw(continuous)/5.5kw(10min./40%ED)

Standard Accessories and Functions

1. CNC unit FANUC 32i-B

2. Operation panel 10.4-inch color LCD display

3. Manual pulse generator

4. Pneumatic unit

5. Hydraulic unit

6. Coolant level detector

7. Automatic centralized lubrication unit

8. Door interlock system

9. Cs contouring control (main/sub)

10. Spindle clamp unit (Main / Sub)

11. Spindle cooling unit

12. Revolving guide bush unit

13. Drive unit for revolving guide bush

14. Air purge for revolving guide bush

15. Main / Sub collet

16. 6-station tool holder 16mm

17. cross drilling unit (Gang type tool post)

18. Drive unit for power-driven (Gang type tool post)

19. 5-spindle sleeve holder

20. Broken cutoff tool detector

21. Backworking attachment

22. Back 6-spindle unit *TypeA

23. 8-spindle backworking unit with Y axis control function *TypeB

24. Sub spindle air purge unit

25. Drive unit for power-driven(Back 8-spindle unit) *TypeB

26. Parts conveyor

27. Work light

28. Leakage brake

RETURN

to listing display

RETURN

to our home page